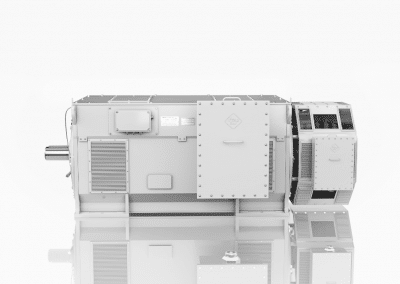

European manufacture electric motors

The production program of VYBO Electric focuses primarily on quality.

The main advantages of the company are: high quality, flexibility, short delivery times and a very wide range of electric motor production. The company has a very rich experience in manufacturing and supplying various types of electric motors.

It can design and manufacture an electric motor for precise customer requirements.

Stator frames:

gray cast iron for ribbed frame

also welded frames for finned electric motors due to certain advantages

welded tubular frames

Welded modular designs for high power electric motors

also modular frames in gray cast iron

special aluminum frames for low weight applications.

rotors:

Rotor with closed squirrel cage – copper rotor cage

Rotor with closed squirrel cage – aluminum rotor cage

slip ring rotors

rotors with double copper cages

winding:

all windings are solved with high-tech VPI technology

(more information on questions for projects)

testing:

We perform type tests, piece tests

Full load testing after electric motor production (up to 10MW)

Routine tests

and others …

VYBO Electric is ranked among the top quality.

Our main products

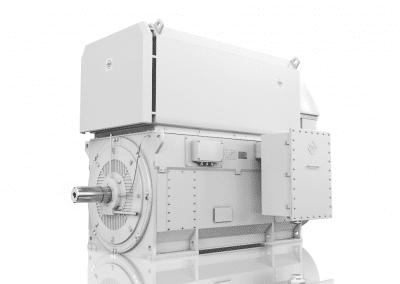

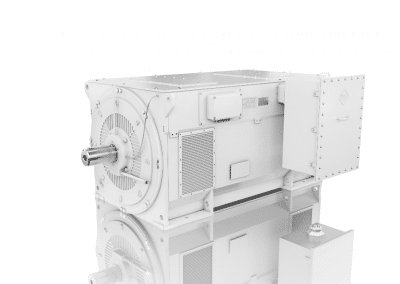

H17R series

Medium and high voltage electric motors in IC411 and IC416 cooling, possible IC511.

More info about medium and high voltage IC411 motors here.

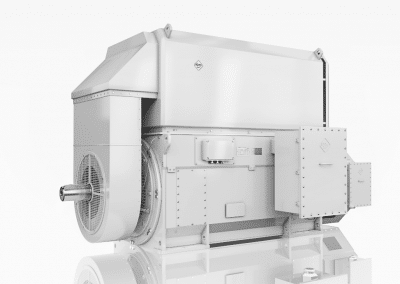

H17RL series

Low voltage big power compact frame electric motors.

More information here.

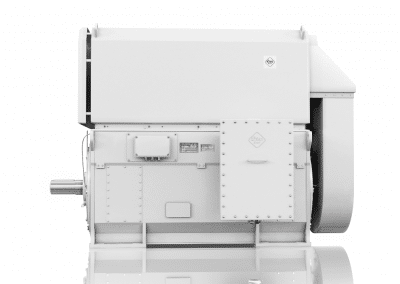

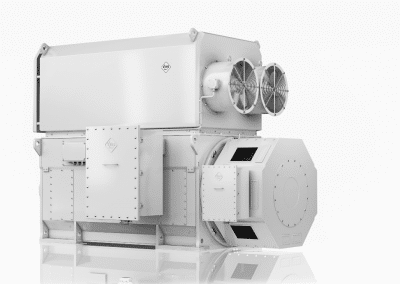

H27R series

Medium and high voltage modular frame electric motors.

More info here.

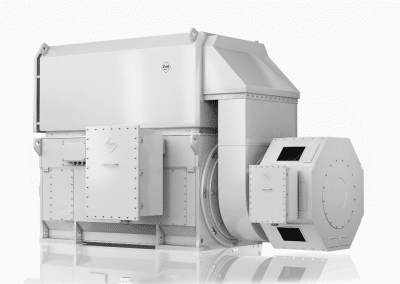

H27R-SR series

High voltage modular frame electric motors.

More info here.

3LC series

Low voltage IEC 55kW and more.

More info here.

Our other products can be found on our homepage here.