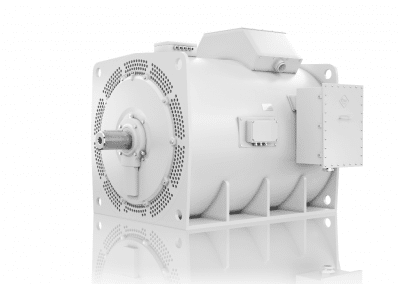

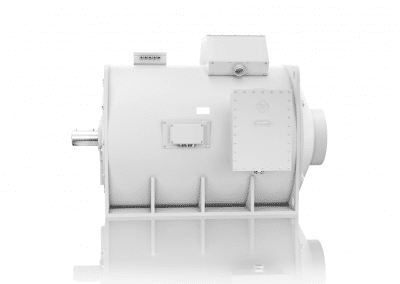

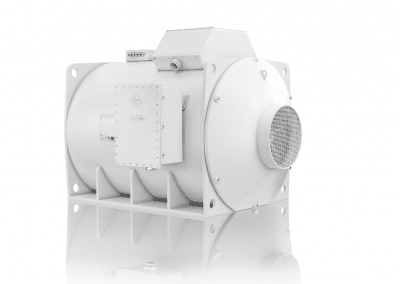

High voltage motors IC511

Medium and high voltage electric motors with tube cooling IC511 H27RT series

| Type of electric motor: | H27RT |

| TEFC | Totally enclosed fan cooled three phase asnychronous electric motor, can be equipped with ventilation |

| Frame sizes: | 355mm-900mm |

| Power range: | 132kW-7000kW |

| Voltage: | 1000V-13800V (Cusomized too on low voltage-380-1000V) |

| Frame material: | welded frame |

| Protection: | IP55,65,67 |

| Cooling: | IC511,IC516(tube cooled) |

| Mounting: | B3,B35,V1,IM V15 |

| Number of poles: | 2-40 |

| Frequency: | 50Hz,60Hz (and customized…) |

| Possible: | Special winding of VFD use,can support several kinds of voltage and frequency |

| Accessories: | PT100,PTC and other thermal elements can be chose to protect bearings and winding Heaters, anti-vibrations senzors and other |

Online contact

00421 948 834 888

(international sales manager)

Email: fv@vyboelectric.eu